You know, when we talk about impressive structures – skyscrapers, massive bridges, even those huge industrial complexes – what's the unsung hero holding it all together? More often than not, it's the humble, yet incredibly robust, construction steel plates. Seriously, these aren't just any old pieces of metal; they're engineered marvels, vital for safety and longevity in demanding applications. I've been in this industry for quite a while, and honestly, the advancements we've seen are quite staggering.

What's Driving the Steel Plate Market? Industry Trends I'm Seeing

If you ask me, the biggest trend right now is the relentless push for higher strength-to-weight ratios. Everyone wants lighter, yet stronger, materials. Why? Because it reduces material costs, simplifies logistics, and improves structural efficiency. We're seeing more high-strength low-alloy (HSLA) steels like the Q355 series becoming standard. Also, there’s a growing demand for improved weldability and enhanced corrosion resistance, especially in coastal or harsh environments. Sustainability is another big one; clients are increasingly asking about recycled content and greener manufacturing processes, which is great to see.

Diving Deep: Technical Specs and The Rise of Q355

Let's get a bit technical, shall we? When we talk about construction steel plates, especially for high-load applications, grades like Q355 are often at the forefront. Q355 steel, actually, has replaced the older Q345, marking a significant step up in performance. The 'Q' stands for yield point, and '355' indicates its minimum yield strength in megapascals (MPa). It's a low-alloy, high-strength structural steel, making it ideal for welded structures that really need to hold up under stress. It also boasts excellent mechanical properties, good weldability, and decent corrosion resistance.

Q355 Series: A Snapshot of Key Mechanical Properties

|

Grade |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

Impact Energy (J) (at specified temp) |

|

Q355B |

≥355 |

470-630 |

≥20 |

≥27 (at 0°C) |

|

Q355C |

≥355 |

470-630 |

≥20 |

≥34 (at 0°C) |

|

Q355D |

≥355 |

470-630 |

≥20 |

≥27 (at -20°C) |

|

Q420MB |

≥420 |

520-680 |

≥18 |

≥34 (at 0°C) |

|

Q460MB |

≥460 |

550-720 |

≥17 |

≥34 (at 0°C) |

Note: Real-world use may vary slightly based on specific mill, rolling conditions, and testing methods. These values are based on GB/T 1591.

Applications: Where These Plates Really Shine

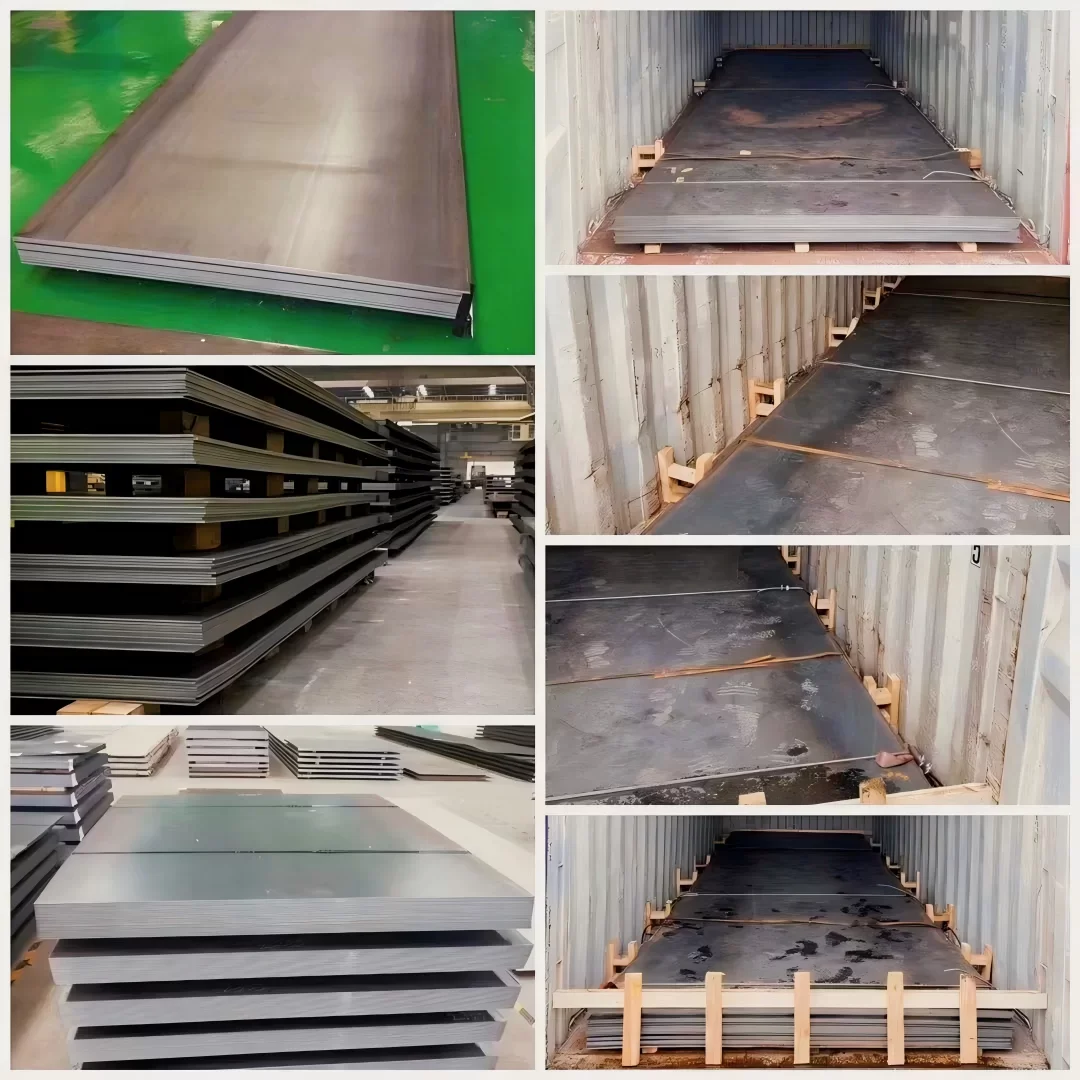

It's amazing how versatile these materials are. Q355, for instance, finds its way into everything from high-rise buildings and bridges to shipbuilding, railway components, and even pressure vessels. Many customers say it's their go-to for complex structures where both strength and weldability are paramount. I've seen it used for petroleum storage tanks, power station equipment, and, crucially, in various types of shipping and waste containers – places where durability is non-negotiable. Basically, if something needs to be strong and withstand significant loads, chances are a construction steel plate like Q355 is involved.

The Journey of a Steel Plate: From Ore to Site

Ever wondered how these fantastic plates come to be? The process is quite involved, actually. It typically starts with raw materials like iron ore, coal, and limestone. These are processed through coking and sintering before ironmaking in blast furnaces. Then comes steelmaking in converters, followed by continuous casting into slabs. The crucial step for plates is hot rolling, where the slabs are heated and passed through rollers to achieve the desired thickness and properties. Post-rolling, the plates undergo various treatments, including normalizing or quenching and tempering, depending on the required mechanical properties. Every batch is rigorously tested against authoritative standards like GB, ASTM, EN, and JIS, ensuring it meets specific mechanical properties, chemical composition, and dimensional tolerances. The service life of a well-maintained structural steel plate can easily span decades, sometimes even a century in less corrosive environments, provided it was correctly specified and installed, of course.

Choosing Your Supplier: It's More Than Just Price

Finding reliable structural steel plate suppliers is absolutely critical. It’s not just about getting the cheapest quote; it’s about quality, consistency, and a partner you can trust. Customization options, lead times, and post-sales support are huge factors. You might need specific dimensions, unique grades, or even specialized surface treatments. A good supplier can handle all that. To be honest, I've seen projects go south because corners were cut on material sourcing. Always check their certifications – ISO, CE, ABS, DNV, LR, etc. – these are your guarantees.

A Quick Comparison: What to Look For

|

Feature |

Supplier A (e.g., BaidySteel) |

Competitor B |

Competitor C |

|

Annual Production Capacity |

10 Million Tons (Iron & Steel) |

Around 5 Million Tons |

Under 2 Million Tons |

|

Product Range |

Extensive (HSLA, Boiler, Shipbuilding, etc.) |

Good, but specialized |

Limited standard grades |

|

Certifications |

Comprehensive (ISO, CE, Lloyd's, etc.) |

Standard certifications |

Basic local standards |

|

Customization Options |

High, specialist grades & sizes |

Moderate customization |

Limited to common sizes |

|

Experience (Founded) |

1992 |

2000s |

2010s |

Case Studies (Generic Examples) & Customer Feedback

While I can't share specific project names here for confidentiality, it seems that high-strength construction steel plates are consistently chosen for large-scale infrastructure. Think of the recent expansion of a major port where heavy-duty cranes and storage facilities demanded Q460MB for its sheer strength. Or a new high-speed rail bridge where Q355D was selected for its excellent low-temperature impact resistance. Customer feedback often highlights the reliability and consistent quality. "We need materials that perform every single time, without fail," one project manager told me recently. That pretty much sums it up, doesn't it?

Concluding Thoughts

It’s clear that construction steel plates are much more than just commodity items. They are the engineered foundation of our modern world, constantly evolving to meet new challenges. From the chemical composition to the precise rolling temperature, every step matters. For any serious construction project, selecting the right grade and a reputable supplier, perhaps one that offers comprehensive customization and robust quality control, is absolutely paramount for success.

Authoritative Citations

1. International Organization for Standardization (ISO) – Standards for steel manufacturing and testing.

2. ASTM International – Standards for materials, products, systems, and services.

3. British Standards Institution (BSI) – European (EN) and national standards for structural steel.

4. Standardization Administration of China (SAC) – GB/T 1591 High strength low alloy structural steels.

Steel Galvanized Automotive Manufacturer We are a foreign trade enterprise specializing in steel export, and Plate Corten Sheet Metal Manufacturer have been deeply engaged in the industry for 18 years, accumulating rich experience and abundant resources. Steel Galvanized Automotive Plate Corten We have a professional team composed of industry elites, who are not only proficient in all kinds of knowledge of steel and familiar with the rules of international trade, but also have keen market insight and excellent communication skills. Whether steel specifications, quality standards, or trade policies and market demand in different countries and regions,Sheet Metal Manufacturer our team can accurately grasp them and provide customers with all-round, one-stop professional services.Xingtai Baidy Steel Works