High Tensile Steel Sheet: field notes from a hands-on buyer’s market

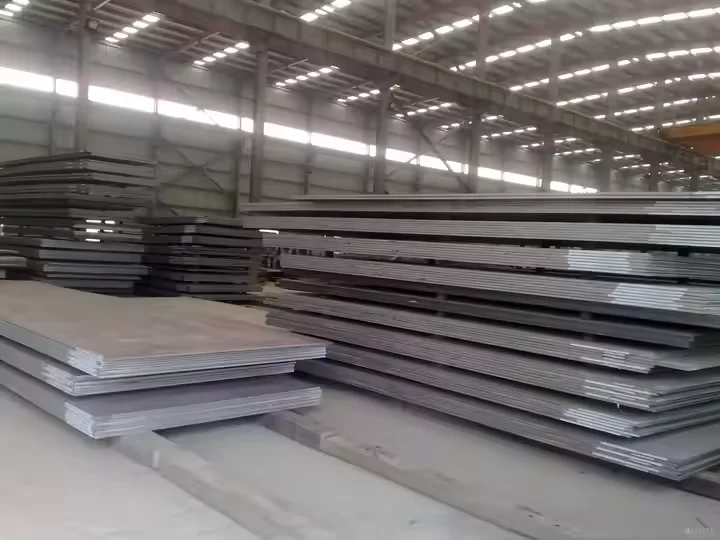

If you’ve specced cranes, bridges, or offshore brackets lately, you already know the mood: weight down, strength up, lead times tight. I’ve spent the last month comparing Q550D–Q890D plates in real bids. And, to be honest, the winners blended metallurgy with logistics. The High Tensile Steel Sheet set below (Q550D/Q690D/Q800D/Q890D) is a good snapshot of where value meets reliability right now.

What’s trending (and why it matters)

Two forces drive demand: high-strength redesign (S690-class equivalents) and decarbonization via material light-weighting. Fabricators tell me Q690D is the “sweet spot” for structural upgrades; Q800D/Q890D get the nod where space and bolting patterns are locked. The catch? Weldability and impact toughness must be proven, not promised.

Product snapshot: Q550D–Q890D hot-rolled alloy plate

Origin: ROOM 1616, SHOUJING E-WORLD, XINDU DISTRICT, XINGTAI, CHINA. Typical delivery: around 14 days on standard sizes. Processing services available: bending, welding, decoiling, cutting, punching.

| Grade | Yield (MPa) ≈ | UTS (MPa) ≈ | Elong. % ≈ | CVN @ -20°C (J) ≈ | Thickness | Width | Length |

|---|---|---|---|---|---|---|---|

| Q550D | ≥550 | 650–800 | 16–20 | ≥47 | 0.5–30 mm | 1000/1219/1500 mm | 1–12 m |

| Q690D | ≥690 | 770–940 | 14–17 | ≥47 | 0.5–30 mm | 1000/1219/1500 mm | 1–12 m |

| Q800D | ≥800 | 880–1050 | 12–15 | ≥40 | 0.5–30 mm | 1000/1219/1500 mm | 1–12 m |

| Q890D | ≥890 | 940–1100 | 10–14 | ≥40 | 0.5–30 mm | 1000/1219/1500 mm | 1–12 m |

Process flow (how it’s really made)

- Materials: low-alloy design (typically Mn–Nb–V–Ti microalloying; Q800D/Q890D often quenched & tempered).

- Methods: hot rolling with TMCP; higher grades receive Q&T for strength and toughness balance.

- Testing: tensile per ISO 6892-1, Charpy V-notch per ISO 148-1, hardness ISO 6506-1; UT per EN 10160 or ASTM A578 upon request.

- Dimensional control: EN 10029 or GB/T 709 tolerance classes; thickness tolerance ≈ ±1% (real-world use may vary).

- Welding guidance: preheat and low-hydrogen practice to AWS D1.1; WPS/PQR typically supplied with MTC 3.1 (EN 10204).

- Service life: 20–30 years in C3–C4 environments with coating; longer with metallized or duplex systems.

Where it’s used

Construction and bridges, crane booms, mining buckets and chassis, wind tower internals, offshore nodes, container plates (yes, the slimmer-but-stronger play). Many customers say Q690D cuts mass by 20–30% versus mild steel while keeping deflection in check.

Vendor comparison (what buyers usually ask me)

| Vendor | MOQ | Lead Time ≈ | Custom Cut | MTC (EN 10204 3.1) | Welding Support |

|---|---|---|---|---|---|

| Baidy Steel (Q550D–Q890D) | 5–10 t | ≈14 days | Yes (beveling, blasting, primer) | Yes | WPS/PQR guidance |

| Mill A (EU) | 15 t+ | 3–5 weeks | Yes | Yes | Standard |

| Service Center B (APAC) | 1–3 t | Stock/quick | Yes (CNC) | On request | Basic |

Customization and paperwork that saves headaches

Cut-to-length, beveled edges, shot blasting SA 2.5, shop primer, and UT level S1/S2 are common asks. Certificates: ISO 9001 mill, EN 10204 3.1 MTC, and, when needed, CE/EN 1090 declarations. For welders, low hydrogen consumables and controlled heat input are non-negotiable on High Tensile Steel Sheet.

Case note: urban bridge retrofit

A metro bridge team swapped 25 mm conventional plate for 16 mm Q690D. Weight dropped ≈28%, bolt patterns stayed, and Charpy results averaged 60–75 J at -20°C (shop tests). Surprisingly quiet install—less crane time, fewer deliveries. The maintenance engineer told me, “It just fit.”

Quick spec recap

- Grades: Q550D, Q690D, Q800D, Q890D; technique: hot rolled (Q&T for higher grades).

- Sizes: 0.5–30 mm thick, widths 1000/1219/1500 mm, lengths 1–12 m.

- Applications: container plate, structural frames, booms, heavy equipment.

- Testing: ISO 6892-1 tensile; ISO 148-1 impact; UT per EN 10160/ASTM A578; hardness ISO 6506-1.

Authoritative citations

- GB/T 16270: High strength structural steel plate (Q550–Q960) specification.

- ISO 6892-1: Metallic materials — Tensile testing.

- ISO 148-1: Charpy pendulum impact test.

- EN 10025-6: High yield strength structural steels in the quenched and tempered condition.

- AWS D1.1/D1.1M: Structural Welding Code — Steel; EN 10204:2004 (MTC 3.1).

Steel Galvanized Automotive Manufacturer We are a foreign trade enterprise specializing in steel export, and Plate Corten Sheet Metal Manufacturer have been deeply engaged in the industry for 18 years, accumulating rich experience and abundant resources. Steel Galvanized Automotive Plate Corten We have a professional team composed of industry elites, who are not only proficient in all kinds of knowledge of steel and familiar with the rules of international trade, but also have keen market insight and excellent communication skills. Whether steel specifications, quality standards, or trade policies and market demand in different countries and regions,Sheet Metal Manufacturer our team can accurately grasp them and provide customers with all-round, one-stop professional services.Xingtai Baidy Steel Works