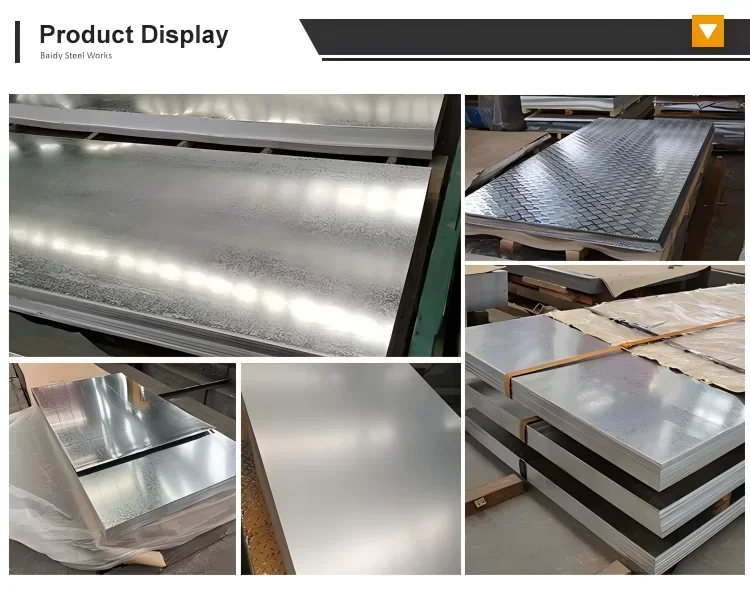

Alright, let's talk steel. Specifically, let's delve into something that's probably been around you more often than you realize: apo galvanized sheet. I’ve been in this industry for quite a while now, and to be honest, the evolution of galvanized steel is truly fascinating. It's not just a boring industrial material; it's a testament to how smart material science can solve persistent problems like, well, rust!

What Exactly Makes These Sheets So Resilient?

At its core, galvanization is a pretty clever process. We're essentially talking about dipping steel into molten zinc. This creates a metallurgical bond, forming a protective zinc coating that acts as a barrier and even provides cathodic protection. Think of it as a sacrificial shield, taking the brunt of corrosion before the underlying steel is affected. It’s a bit more complex than that, of course, involving meticulous cleaning (degreasing, pickling) before the hot-dip phase, followed by a passivation treatment. The result? A remarkably durable product, like the apo galvanized sheet you might find in everything from your roofing to your washing machine. We're seeing service lives extending well beyond what was typical just a couple of decades ago, often 20-50 years, depending on the environment.

Industry Trends: A Shifting Landscape

Actually, the market for galvanized steel is pretty dynamic. There’s a noticeable shift towards higher-strength grades and, surprisingly, an increased demand for customized finishes – from zero spangle (super smooth for painting) to regular spangle for general use. Environmental regulations are also pushing for more sustainable production methods, which is a good thing, don't you think? Many customers say they're looking for suppliers who can demonstrate robust environmental compliance and offer reliable traceability. It seems that the days of just "steel is steel" are long gone.

Breaking Down the Specs: What You Need to Know

When we talk about grades like DX51D+Z, DX52D+Z, or S550GD+Z, we're essentially defining the steel's formability and strength. DX51D+Z, for instance, is a common choice for general forming, while S550GD+Z offers much higher yield strength, perfect for structural applications where rigidity is key. Here's a quick look at some common specifications for a high-quality apo galvanized sheet you might find for sale:

|

Typical APO Galvanized Sheet Specifications |

|

|

Feature |

Detail |

|

Standard |

ASTM, EN, DIN, GB, JIS (meeting international norms) |

|

Grades |

DX51D+Z, DX52D+Z, S550GD+Z (and more) |

|

Technique |

Cold Rolled Based (ensuring smooth finish) |

|

Galvanized Spangles |

Zero, Small, Regular, Large (aesthetic and functional choice) |

|

MOQ |

Around 1 Ton (can vary slightly by supplier) |

|

Delivery Time |

5-14 days (real-world use may vary based on quantity/location) |

|

Price Terms |

FOB, CRF, CIF, EXW (all acceptable options) |

Where Do These Sheets Really Shine?

Honestly, the application scenarios for apo galvanized sheet are incredibly diverse. You see them everywhere: in the construction sector for roofing, wall panels, and structural components; in automotive parts (think car bodies and exhaust systems); for household appliances like refrigerators and washing machines; and even in HVAC ducts. The ability to resist harsh weather, chemicals, and general wear and tear makes them indispensable. I once saw a roof made with these sheets still looking good after nearly forty years in a coastal environment – that’s pretty impressive longevity, if you ask me.

Navigating the Market: Vendor Comparison and Customization

When you're looking for a good galvanized sheet for sale, it's not just about the lowest price, believe me. Quality, consistency, and after-sales support really matter. Certifications (like ISO 9001, CE, ASTM standards) are non-negotiable proof of adherence to authoritative standards and testing. Also, don't underestimate customization. The right vendor should be able to offer specific dimensions, coatings, and even specialized packing (plastic film + Kraft paper + strapping + wooden pallet/box – customizable!) to suit your project needs.

|

Vendor Comparison: Key Considerations |

||

|

Factor |

Good Vendor Traits |

Points to Watch Out For |

|

Product Quality & Consistency |

Consistent spangle, uniform coating, adherence to grade specs. |

Irregular coating, inconsistent thickness, unclear origin. |

|

Certifications & Standards |

ISO, ASTM, EN, JIS certified; readily provides test data. |

Missing or outdated certifications, reluctance to share test reports. |

|

Customization & Flexibility |

Offers various grades, spangles, dimensions, and packing options. |

Limited options, rigid MOQ, slow response to special requests. |

|

Delivery & Logistics |

Reliable delivery times, clear communication on shipping. |

Frequent delays, vague delivery estimates, poor communication. |

A Quick Case Study

I remember a client working on a new agricultural building in a notoriously humid region. They initially considered a cheaper, ungalvanized option, but after our discussions about long-term costs and maintenance, they opted for high-grade apo galvanized sheet. Three years on, they've reported zero issues with rust or structural integrity, even with constant exposure to moisture and fertilizers. The initial investment was slightly higher, yes, but the long-term savings on repairs and replacements are already clear. Customer feedback consistently highlights this longevity as a key benefit.

Final Thoughts: The Future is Bright (and Galvanized)

It's clear that the demand for high-quality, durable materials like apo galvanized sheet isn't going anywhere. With ongoing innovations in coating technologies and steel alloys, I guess we’ll only see these products become even more robust and versatile. For anyone in construction, manufacturing, or even just planning a backyard project, understanding the true value and technical prowess of galvanized steel is, in my opinion, absolutely essential. It’s an investment that truly pays off over time.

Authoritative References

1. ASTM International. "Standard Specification for Hot-Dip Galvanized Carbon Steel Sheets, Commercial Quality." ASTM A653/A653M.

2. European Committee for Standardization. "Hot dip galvanized flat products of steels for cold forming – Technical delivery conditions." EN 10346.

3. American Galvanizers Association. "The Durability of Hot-Dip Galvanized Steel."

Steel Galvanized Automotive Manufacturer We are a foreign trade enterprise specializing in steel export, and Plate Corten Sheet Metal Manufacturer have been deeply engaged in the industry for 18 years, accumulating rich experience and abundant resources. Steel Galvanized Automotive Plate Corten We have a professional team composed of industry elites, who are not only proficient in all kinds of knowledge of steel and familiar with the rules of international trade, but also have keen market insight and excellent communication skills. Whether steel specifications, quality standards, or trade policies and market demand in different countries and regions,Sheet Metal Manufacturer our team can accurately grasp them and provide customers with all-round, one-stop professional services.Xingtai Baidy Steel Works