In the intricate world of structural engineering and large-scale infrastructure development, the selection of fundamental materials dictates the longevity, safety, and operational efficiency of any project. Among these critical components, construction steel plates stand out as indispensable. These robust, flat pieces of steel are not merely raw materials; they are the backbone of our built environment, forming the crucial framework for everything from towering skyscrapers to expansive bridges, industrial complexes, and critical energy infrastructure. Their versatility stems from their exceptional strength-to-weight ratio, durability, and adaptability, making them a preferred choice for architects, engineers, and construction firms globally. Understanding the nuances of these plates—their grades, fabrication, and performance characteristics—is paramount to ensuring structural integrity and achieving design specifications. This exploration delves into the profound impact and technical sophistication embedded within these essential building blocks, highlighting why their meticulous selection and application are non-negotiable for modern construction.

The Unseen Strength: Market Dynamics and Demand Drivers

The global demand for high-quality steel plates, particularly those tailored for construction, reflects a surging trend in urbanization and infrastructure investment. Recent market analyses underscore this robust growth trajectory. According to a comprehensive report by Grand View Research, the global structural steel market size was valued at approximately USD 120 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This upward trend is primarily fueled by monumental government initiatives in developing nations aimed at improving transportation networks, housing, and industrial capabilities, alongside ongoing revitalization projects in mature economies. Consider, for instance, the sheer volume of steel plates required for a single major bridge project, often exceeding tens of thousands of tons. This massive demand translates into significant logistical and manufacturing challenges, pushing producers to innovate in terms of material science, production efficiency, and supply chain reliability. The evolving landscape of sustainable construction also plays a pivotal role, with a growing emphasis on recyclable materials and manufacturing processes that minimize environmental impact. The drive towards building resilient structures capable of withstanding extreme weather events and seismic activity further intensifies the need for advanced, high-performance steel plates, positioning them at the forefront of resilient urban development.

Engineering Excellence: Superior Properties and Performance Benefits

The widespread adoption of steel plates in construction is not arbitrary; it is a direct consequence of their superior mechanical properties and inherent performance benefits. Modern metallurgy has enabled the production of steel plates with an astonishing array of characteristics, each tailored for specific structural demands. Key advantages include their unparalleled tensile strength, allowing them to withstand significant pulling forces without fracturing, and their impressive yield strength, which denotes the maximum stress they can endure before permanent deformation. Furthermore, properties such as exceptional weldability facilitate efficient fabrication and assembly on-site, reducing construction timelines and costs. High impact toughness ensures resistance to sudden loads and brittle fracture, crucial for structures exposed to dynamic forces or low temperatures. Corrosion resistance, often enhanced through alloying elements or protective coatings, extends the lifespan of structures, particularly in harsh marine or industrial environments. Fire resistance is another critical aspect, with specialized grades designed to maintain structural integrity at elevated temperatures for extended periods, providing crucial evacuation time in emergencies. The consistency in material properties, guaranteed by rigorous manufacturing standards and certifications like ASTM, EN, and JIS, instills confidence in structural engineers. These combined attributes make steel plates a highly reliable, cost-effective, and adaptable material, underpinning the safety and longevity of contemporary architectural and engineering marvels.

Navigating the Landscape: A Comparative Look at Leading Manufacturers

Choosing the right manufacturer for construction steel plates is a decision that can significantly impact project timelines, budget, and ultimately, structural integrity. The market is populated by numerous reputable producers, each with distinct strengths in terms of product range, technological capabilities, and service offerings. Evaluating these differences is crucial for procurement specialists. Below is a simplified comparison highlighting key areas:

|

Feature |

Manufacturer A (e.g., Global Steel Solutions) |

Manufacturer B (e.g., Apex Metals Group) |

Manufacturer C (e.g., Dynasteel Corp.) |

|

Primary Focus |

High-strength, low-alloy (HSLA) plates for bridges & offshore |

Standard structural grades (A36, A572) & custom fabrication |

Specialty grades (wear-resistant, fire-resistant) & large dimensions |

|

Certifications & Standards |

ISO 9001, CE, ASTM, API, Lloyd's Register |

ISO 9001, ASTM, AISC Certified Fabricator |

ISO 9001, CE, EN, DNV, ABS |

|

Lead Times (Standard Orders) |

Typically 2-4 weeks |

1-3 weeks (larger stock) |

3-6 weeks (specialized production) |

|

Customization Capabilities |

Advanced plasma cutting, bending, drilling, welding. Highly flexible. |

Basic cutting, punching. Partners for complex fabrication. |

Extensive pre-processing: large-scale cutting, rolling, coating lines. |

|

Geographic Reach |

Global distribution network, strong in Europe & Asia |

Strong presence in North America & South America |

Focus on high-demand projects globally, specialized logistics |

|

Sustainability Initiatives |

Significant investment in green steel production, carbon reduction targets. |

Recycling programs, energy-efficient operations. |

Focus on product longevity, reduced material waste during production. |

|

Typical Project Scale |

Mega-infrastructure, complex industrial facilities |

Mid-to-large commercial buildings, standard industrial |

Specialized industrial, extreme environment structures |

This table illustrates that while all are capable suppliers, their strengths vary. Manufacturer A might be ideal for complex, high-stress applications requiring stringent certifications, while Manufacturer B could be preferred for projects with tighter deadlines and standard grade requirements. Manufacturer C excels in niche, high-performance applications that demand specific material characteristics or exceptionally large plate sizes. A thorough assessment of project-specific needs against a manufacturer's core competencies is paramount to a successful partnership.

Tailored Solutions: Precision Engineering for Unique Project Demands

The days of one-size-fits-all steel are long gone. Modern construction projects frequently demand highly specific material properties and dimensions, necessitating advanced customization solutions for steel plates. Reputable suppliers offer a spectrum of value-added services that transform raw plates into ready-to-assemble components, minimizing on-site fabrication and reducing waste. This includes precision cutting techniques such as laser, plasma, and oxy-fuel cutting, capable of producing intricate shapes and profiles with exacting tolerances. Drilling, punching, and notching services are also commonly available, pre-preparing plates for bolt connections or specific structural interfaces. Furthermore, specialized forming and rolling capabilities allow for the creation of curved or bent plates, essential for architectural aesthetics or specific engineering requirements like pressure vessels and curved bridge sections. Surface treatments, including shot blasting and primer application, enhance corrosion resistance and prepare plates for subsequent painting or coating. For projects in extreme environments, custom heat treatments can optimize mechanical properties, while specialized welding procedures ensure the integrity of complex assemblies. The ability to source plates with specific chemical compositions, controlled rolling processes, or even dual certifications (e.g., meeting both ASTM and EN standards) provides engineers with unparalleled flexibility. By leveraging these customization options, construction firms can achieve greater design freedom, streamline their workflows, and significantly improve project efficiency and safety.

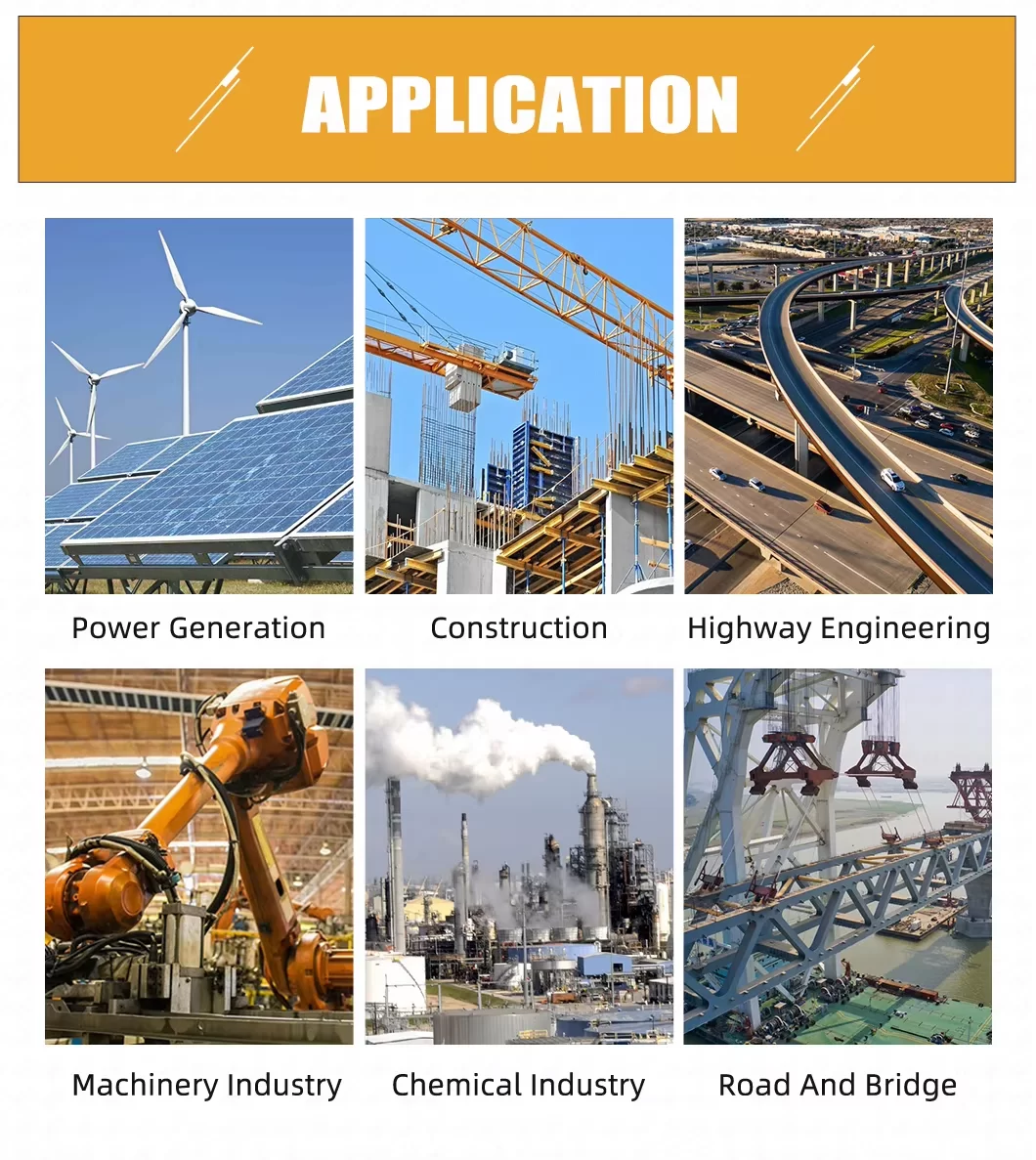

Building the Future: Diverse Applications Across Industries

The versatility of steel plates means they are integrated into an astonishing array of applications, forming the critical components across virtually every sector of the built environment. In civil engineering, they are fundamental to bridge construction, providing the main girders, deck plates, and bracing elements that support colossal loads and withstand environmental stresses. High-rise buildings rely on heavy steel plates for their core structural components, including floor plates, shear walls, and foundational elements, offering superior strength and ductility in seismic zones. The energy sector utilizes steel plates extensively in the construction of oil and gas platforms, wind turbine towers, and power plant structures, where resistance to extreme temperatures, pressures, and corrosive agents is non-negotiable. For marine and shipbuilding, specialized grades of steel plate are crucial for hulls, decks, and bulkheads, designed to endure harsh saltwater environments and dynamic oceanic forces. Even in heavy machinery and industrial equipment, such as cranes, excavators, and mining apparatus, robust steel plates form the chassis and structural frames, providing the necessary durability and fatigue resistance for demanding operational cycles. From architectural marvels that push the boundaries of design to the hidden foundations that support our daily lives, steel plates are an omnipresent testament to engineered strength, quietly upholding the progress and ambition of human ingenuity.

Investing in Durability: The Long-Term Value of Quality Construction Steel Plates

The procurement of high-quality construction steel plates is far more than a simple material acquisition; it is a strategic investment in the long-term integrity, safety, and economic viability of any structural endeavor. Cutting corners on material quality can lead to catastrophic failures, costly repairs, and significant reputational damage, dwarfing any initial savings. By prioritizing certified, precisely manufactured steel plates from reputable suppliers, project stakeholders secure peace of mind, knowing their structures are built on a foundation of proven strength and resilience. The upfront cost difference between premium and substandard materials is often negligible when weighed against the extended service life, reduced maintenance requirements, and enhanced safety performance offered by superior steel. Moreover, the environmental benefits of durable construction are increasingly recognized; longer-lasting structures consume fewer resources over their lifecycle and generate less waste. As the global construction industry continues to evolve, driven by demands for greater sustainability, resilience, and efficiency, the role of advanced steel plates will only become more pronounced. Choosing wisely means building not just for today, but for generations to come, ensuring our infrastructure remains robust, reliable, and capable of meeting future challenges.

Frequently Asked Questions About Construction Steel Plates

What are the most common grades of construction steel plates?

Common grades include ASTM A36 for general structural applications, ASTM A572 Grade 50 for higher strength, and ASTM A514 for high-strength, low-alloy quenched and tempered plates. European standards include EN 10025 grades like S235, S275, and S355.

How do steel plates contribute to a building's seismic resistance?

Steel plates provide ductility, meaning they can deform significantly under stress without fracturing. This allows steel-framed structures to absorb and dissipate seismic energy, preventing sudden collapse and providing valuable time for evacuation, which is crucial during an earthquake.

What is the difference between hot-rolled and cold-rolled steel plates?

Hot-rolled steel plates are processed at high temperatures, making them easier to form and typically more cost-effective for large structural components. Cold-rolled steel plates are processed at room temperature, resulting in a smoother finish, tighter tolerances, and increased strength, often used for precision components or aesthetic applications.

Can construction steel plates be recycled?

Absolutely. Steel is one of the most recycled materials globally. Construction steel plates can be melted down and reformed into new steel products almost indefinitely without losing their inherent properties, making them a highly sustainable choice for construction.

What factors influence the cost of construction steel plates?

Costs are influenced by raw material prices (iron ore, scrap), energy costs, manufacturing processes, steel grade (alloying elements), plate dimensions (thickness, width, length), market demand, and additional services like cutting, drilling, or surface treatments.

How should construction steel plates be stored to prevent degradation?

They should be stored in a dry, covered area to prevent rust and corrosion, elevated off the ground to avoid moisture contact. Stacking should be done carefully to prevent warping or bending, and different grades or sizes should be clearly marked and segregated.

What are typical surface finishes available for construction steel plates?

Standard finishes include mill finish (as-rolled). Further processing can include shot blasting (for cleaning and surface profiling), priming (for corrosion protection and paint adhesion), or galvanization for enhanced long-term corrosion resistance in specific environments.

Steel Galvanized Automotive Manufacturer We are a foreign trade enterprise specializing in steel export, and Plate Corten Sheet Metal Manufacturer have been deeply engaged in the industry for 18 years, accumulating rich experience and abundant resources. Steel Galvanized Automotive Plate Corten We have a professional team composed of industry elites, who are not only proficient in all kinds of knowledge of steel and familiar with the rules of international trade, but also have keen market insight and excellent communication skills. Whether steel specifications, quality standards, or trade policies and market demand in different countries and regions,Sheet Metal Manufacturer our team can accurately grasp them and provide customers with all-round, one-stop professional services.Xingtai Baidy Steel Works