Q420q D/E Bridge Steel: a field-tested guide from the shop floor

If you’re speccing plates or sections for long-span decks, towers, or orthotropic panels, you’ve surely bumped into

q420 steel.

It sits in that sweet spot: high yield, stable weldability, and—when ordered right—reliable toughness for cold nights on site. I’ve seen it solve weight problems on box girders more than once, to be honest.

What it is (and why bridge teams like it)

The product line most buyers ask me about is “Q345q Q370q D/E Q420q D/E Structural Steel For Bridges.” The D/E suffix signals impact toughness class (D for sub-zero, E for colder), which matters for fatigue-prone details. In practice, q420 steel helps shave mass from webs and flanges while maintaining stiffness and design life targets around 100 years—assuming coatings and inspection cycles are done right.

Specification snapshot (typical)

| Item | Typical Value/Range | Standard/Note |

| Yield strength (t ≤ 50 mm) | ≥ 420 MPa | GB/T 714 (Q420q) |

| Tensile strength | ≈ 520–680 MPa | ISO 6892-1 method |

| Charpy V-notch | D: around -20°C; E: around -40°C (≥ 27–47 J, thickness-dependent) | ISO 148-1; real-world use may vary |

| Thickness / Width / Length | 6–100 mm / 900–4800 mm / 3000–25000 mm | Custom cuts available |

| Shapes | Plate, H/I-beam, angle, channel | HSLA, bridge-grade |

| Technique | TMCP or QT; some thin gauges cold-rolled | Mill-dependent |

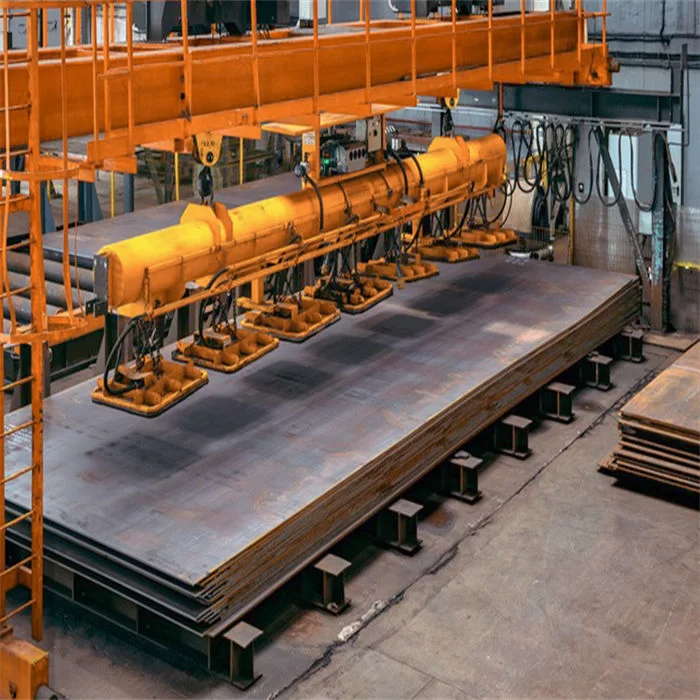

Process flow and quality gates

Materials: HSLA melts with microalloying (Nb/V/Ti), controlled sulfur for weldability, optional Z-direction properties (Z15/Z25/Z35) to resist lamellar tearing. Methods: steelmaking → continuous casting → TMCP or QT → leveling → shot blasting/priming → cutting and beveling. Testing: tensile (ISO 6892-1), impact (ISO 148-1), UT per EN 10160 or ASTM A578, plus dimensions/surface checks. I’ve seen many buyers ask for UT Class S2/E3 and it’s a smart move on thick webs. Service life: typically designed for 50–100 years with proper corrosion systems and inspection cycles. Industries: bridges (obviously), heavy civil gantries, large-span roofs where high yield trims tonnage.

Real-world use: a quick case

Cable-stayed deck upgrade, coastal region, winter spec. The team moved from Q370qE to q420 steel (40 mm plate, E-grade). Welds qualified to AWS D1.5 with low-hydrogen consumables; preheat ~120°C, interpass controlled. UT to EN 10160 S2/E3, zero recordable indications on main girder splices. Net result: ≈9% weight reduction on the panel line and better fatigue margins at U-rib terminations. The fabricator told me the cutting edges were cleaner than expected—pleasant surprise.

Vendor comparison (quick take)

| Vendor | Key Strengths | Lead Time | Certs/Options |

| Baidy Steel (Hebei, China) ROOM 1616, SHOUJING E-WORLD, XINDU DISTRICT, XINGTAI |

Bridge-grade focus; wide size window; reasonable MOQ | ≈15–21 days (ex-mill), project-dependent | ISO; UT per EN 10160/ASTM A578; Z15–Z35; coatings |

| Mill A (Global OEM) | TMCP/QT depth; strong third-party QA | 4–8 weeks typical | EN 10025-6, CE marking, AWS D1.5 WPS support |

| Stockist B (EU) | Faster small-batch deliveries; cut-to-length | 1–2 weeks ex-stock | Mill cert 3.1; limited thickness range |

Customization and tips

- Order q420 steel with specified impact class (D/E) and UT level; note flange/web thickness breaks.

- Request Z15/Z25/Z35 when through-thickness welds appear near high-restraint joints.

- For welding, use low-hydrogen processes; qualify per AWS D1.5; consider preheat and interpass caps.

- Surface prep: shot blast + shop primer improves fabrication flow and inspection visibility.

Standards you’ll see on the MTC

GB/T 714 for bridge plates, ISO 6892-1 for tensile, ISO 148-1 for Charpy, EN 10160 or ASTM A578 for UT, and AWS D1.5 for welding. Some clients cross-check with ASTM A709 equivalencies, though grades are not 1:1—just be cautious.

Product basics (from the line)

Standards: ISO, ASTM/ASME/AISI, EN, GB/T, DIN, JIS, BS. Thickness 6–100 mm, width 900–4800 mm, length 3000–25000 mm; shapes include plate and profiles. Origin: Hebei, China. Typical delivery: 15–21 days for regular runs—rush jobs exist, but plan ahead.

Customer feedback

Many customers say q420 steel hits a practical balance: less mass than Q370q, friendlier weldability than some higher-strength imports, and predictable UT results when ordering S2/E3. That matches what I’ve seen in shops, frankly.

References

- GB/T 714: Hot-rolled plates and strips for bridges (Q345q–Q420q series).

- ISO 6892-1: Metallic materials — Tensile testing — Part 1.

- ISO 148-1: Metallic materials — Charpy pendulum impact test — Part 1.

- EN 10160: Ultrasonic testing of steel flat product of thickness ≥ 6 mm.

- ASTM A578/A578M: Standard Specification for Straight-Beam UT Examination of Rolled Steel Plates.

- AWS D1.5: Bridge Welding Code.

Steel Galvanized Automotive Manufacturer We are a foreign trade enterprise specializing in steel export, and Plate Corten Sheet Metal Manufacturer have been deeply engaged in the industry for 18 years, accumulating rich experience and abundant resources. Steel Galvanized Automotive Plate Corten We have a professional team composed of industry elites, who are not only proficient in all kinds of knowledge of steel and familiar with the rules of international trade, but also have keen market insight and excellent communication skills. Whether steel specifications, quality standards, or trade policies and market demand in different countries and regions,Sheet Metal Manufacturer our team can accurately grasp them and provide customers with all-round, one-stop professional services.Xingtai Baidy Steel Works