To be honest, when you think about the backbone of heavy industry – mining, construction, even agriculture – what often comes to mind are the massive machines, the raw power. But what about the materials that make these machines endure? What keeps them from literally grinding to a halt? That, my friends, is where the humble, yet incredibly vital, abrasion resistant plate steps in. It's truly an unsung hero, doing the dirty work day in and day out.

Why Wear Resistance is No Longer Optional

Actually, in today's fast-paced world, downtime is a killer. Every hour a piece of equipment is out of commission due to wear and tear costs significant money, not to mention lost productivity. This is why the demand for truly robust materials like abrasion resistant plate has absolutely skyrocketed. Industry trends show a clear shift towards materials that offer extended service life, reduced maintenance, and ultimately, a lower total cost of ownership. It’s not just about initial purchase price anymore; it’s about the long game, folks.

The Core: Understanding NM Grades

Let's get a bit technical, shall we? When we talk about abrasion resistant plate, especially within the Chinese domestic steel standard, we're often looking at grades like NM360, NM400, NM450, and NM500. These numbers, believe it or not, directly correlate to the Brinell hardness (HBW) of the steel. Higher numbers mean harder steel, which generally translates to better wear resistance. But it's not just about hardness; these plates are engineered for a delicate balance:

· NM360 & NM400: Great all-rounders, offering a fantastic blend of hardness, impact toughness, and weldability. Perfect for medium-wear applications.

· NM450 & NM500: These are the heavy hitters, designed for extreme wear and high-impact scenarios where other steels just wouldn't cut it.

Surprisingly, despite their toughness, these plates also often serve as high strength structural steel, boasting yield strengths exceeding 800MPa! That's impressive, I guess, considering their primary role is to resist grinding. This dual functionality is a real game-changer for designers.

Technical Specs at a Glance

|

Grade |

Hardness (HBW) |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Typical Thickness (mm) |

|

NM360 |

340-390 |

>800 |

>1050 |

6-60 |

|

NM400 |

370-430 |

>1000 |

>1250 |

6-60 |

|

NM450 |

420-480 |

>1200 |

>1400 |

6-50 |

|

NM500 |

470-530 |

>1400 |

>1600 |

8-40 |

Note: Real-world use performance may vary based on specific application and environment. Values are typical and subject to standard tolerances.

Where These Plates Shine: Application Scenarios

So, where exactly do you find these robust plates? Pretty much anywhere there's heavy abrasion and impact, actually. Think about it: the buckets of excavators and loaders, the cutting edges of bulldozers, the liners of crushers that are constantly processing rocks and minerals. That's where wear steel plate proves its worth. Industries from mining and quarrying to construction, cement production, and even agriculture heavily rely on these materials.

· Construction: Excavator bucket plates, bulldozer blades, truck dump bodies.

· Mining & Quarrying: Crusher liners, chutes, conveyor components, screening plants.

· Cement & Aggregate: Mixer drums, fan blades, hopper liners.

Many customers say that using specific grades for specific parts – NM360 for general bucket sides, perhaps NM500 for critical cutting edges – truly optimizes performance and lifecycle costs. It just makes sense.

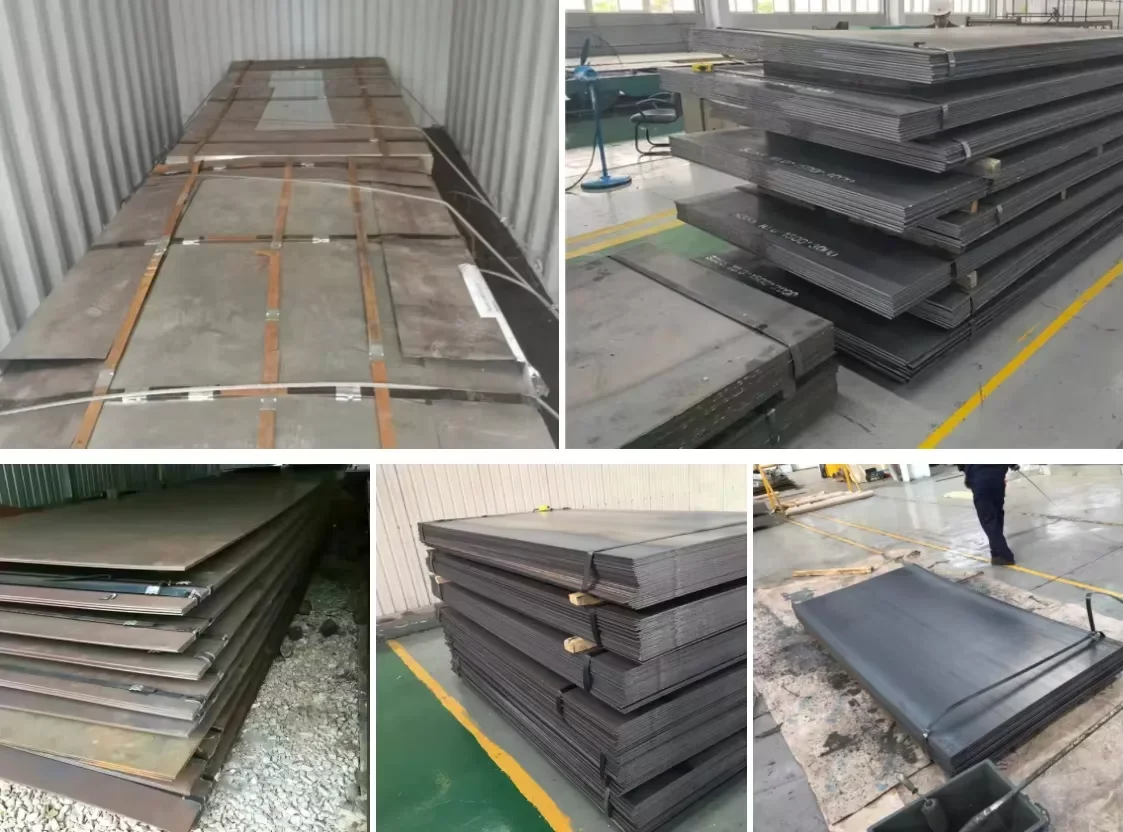

The Manufacturing Edge: Quality Control and Customization

Creating a high-quality abrasion resistant plate isn't just about mixing iron and carbon. It's a precise process. It starts with carefully selected raw materials, followed by advanced steelmaking processes, and crucially, sophisticated heat treatment – typically quenching and tempering – to achieve that optimal balance of hardness and toughness. Each batch undergoes rigorous testing for hardness, impact toughness (often Charpy V-notch tests), and chemical composition to ensure it meets stringent authoritative standards. Certifications like ISO 9001 are pretty much a given for reputable manufacturers, assuring that their processes are up to snuff.

And customization? Absolutely! Whether it's specific plate dimensions, drilling, cutting, or even custom fabrication, a good vendor can tailor these plates to your exact project needs. This flexibility is a huge advantage, enabling seamless integration into existing designs or completely new ones.

Choosing Your Supplier: A Quick Guide

|

Factor |

What to Look For |

|

Product Range |

Availability of NM360, NM400, NM450, NM500 and various thicknesses. |

|

Certifications |

ISO, CE, and adherence to international/national standards. |

|

Customization |

Cutting, drilling, welding services; project-specific solutions. |

|

Lead Time & Logistics |

Reliable delivery, efficient supply chain. |

|

Technical Support |

Expert advice on material selection, welding, and fabrication. |

The Bottom Line: Real Value, Proven Performance

Ultimately, investing in quality abrasion resistant plate isn't just an expense; it's an investment in the longevity and efficiency of your operations. The advantages are clear: extended service life for critical components, drastically reduced downtime for repairs, lower maintenance costs over the equipment's lifespan, and improved safety as structural integrity is maintained longer. From what I've seen, companies that embrace these advanced materials consistently report better operational figures. It's truly a win-win.

Authoritative Citations

1. International Organization for Standardization (ISO) – Standards for quality management and materials.

2. ASTM International – Standards for testing and materials.

3. SSAB Hardox Wearparts Handbook – Industry reference for wear steels and applications.

Steel Galvanized Automotive Manufacturer We are a foreign trade enterprise specializing in steel export, and Plate Corten Sheet Metal Manufacturer have been deeply engaged in the industry for 18 years, accumulating rich experience and abundant resources. Steel Galvanized Automotive Plate Corten We have a professional team composed of industry elites, who are not only proficient in all kinds of knowledge of steel and familiar with the rules of international trade, but also have keen market insight and excellent communication skills. Whether steel specifications, quality standards, or trade policies and market demand in different countries and regions,Sheet Metal Manufacturer our team can accurately grasp them and provide customers with all-round, one-stop professional services.Xingtai Baidy Steel Works