You know, in the world of construction and manufacturing, certain materials just silently do the heavy lifting, day in and day out. One such unsung hero, in my opinion, is the apo galvanized sheet. It's more than just steel with a shiny coat; it's a testament to engineering that tackles corrosion head-on, ensuring longevity in all sorts of demanding environments. I've seen firsthand how crucial its performance is, from towering skyscrapers to the humble washing machine in your laundry room, actually.

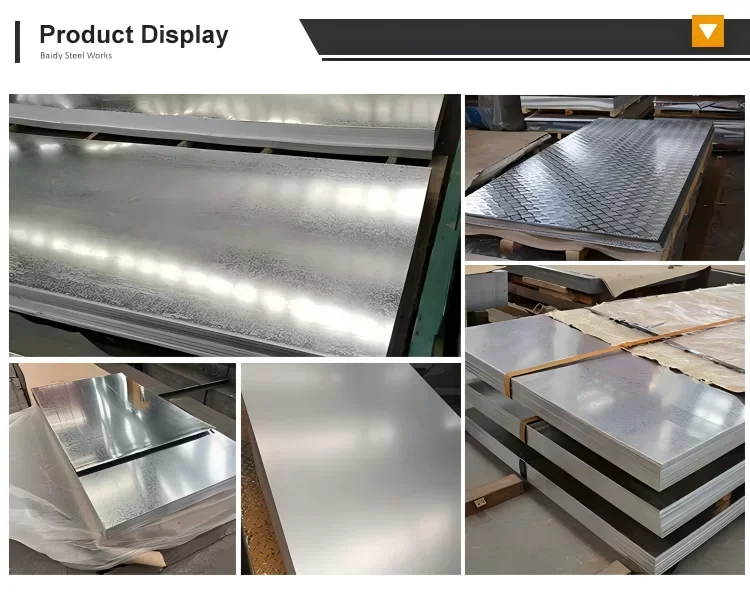

When we talk about apo galvanized sheet, we're really diving into a category of galvanized steel renowned for its enhanced properties and reliable performance. Take for example, products like the Galvanized Steel Sheet DX51D+Z, DX52D+Z, and S550GD+Z – these are prime examples of what makes this material so vital. They are, essentially, steel sheets that have undergone a rigorous galvanization process, giving them that characteristic zinc coating that acts as a sacrificial barrier against rust. It's pretty clever, if you ask me.

The Alchemy of Protection: How It's Made

So, how do we get from raw steel to these incredibly durable sheets? Well, it's a fascinating journey. Most of the high-quality apo galvanized sheet starts as a cold-rolled base. This ensures a consistent thickness and a smooth surface, which is absolutely critical for the subsequent galvanizing process. Once the cold-rolled sheet is prepared, it's then submerged into a bath of molten zinc. This is the 'hot-dip' part of the process, and it creates a metallurgical bond between the steel and the zinc.

The thickness of this zinc coating, often measured in grams per square meter, directly correlates to the material's corrosion resistance. After dipping, the sheet cools, and the zinc solidifies, forming distinct crystalline patterns called spangles. You can actually specify the type of spangle – zero, small, regular, or large – depending on the aesthetic and functional requirements. Zero spangle, for instance, often means a smoother finish, great for painting. The testing standards are rigorous, adhering to international benchmarks like ASTM, EN, DIN, GB, and JIS, ensuring consistent quality across the board. Real-world service life, to be honest, can extend for decades, sometimes 50 years or more, depending on the environment.

Technical Rundown: What to Look For

When you're sourcing high-performance apo galvanized sheet, understanding the specs is key. Here’s a quick overview of what a typical product, like the Galvanized Steel Sheet DX51D+Z, DX52D+Z, S550GD+Z, brings to the table:

|

Feature |

Specification (e.g., Baidy Steel) |

|

Standard Compliance |

ASTM, EN, DIN, GB, JIS |

|

Grades Available |

DX51D+Z, DX52D+Z, S550GD+Z (among others) |

|

Technique |

Cold Rolled Based |

|

Galvanized Spangles |

Zero, Small, Regular, Large |

|

Minimum Order Quantity (MOQ) |

≈ 1 Ton (varies by supplier/product) |

|

Delivery Time |

Typically 5-14 days |

|

Price Terms |

FOB, CRF, CIF, EXW (all acceptable) |

|

Packing Options |

Plastic film + Kraft paper + Strapping + Wooden pallet/Box (Customizable for shipping) |

Applications & Advantages: Where It Shines

It seems that almost every industry benefits from the robust nature of apo galvanized sheet. Its primary advantage is, of course, unparalleled corrosion resistance, but it's also incredibly formable and weldable. You'll find it extensively in construction for roofing, siding, and structural components. In the automotive sector, it's used for body panels and chassis parts, extending vehicle life considerably. HVAC systems, electrical enclosures, and even everyday appliances like refrigerators use galvanized steel because, let's be honest, nobody wants rust invading their home goods.

Many customers say that its low maintenance and long service life offer a fantastic return on investment, which is a big deal when you're thinking about long-term projects. This also aligns with current industry trends towards more sustainable and durable materials, reducing the need for frequent replacements.

Choosing Your Supplier: A Quick Comparison

When you're looking for galvanized tin sheets for sale, selecting the right vendor is paramount. It’s not just about price; it’s about quality, reliability, and support. A good supplier, like Baidy Steel, which was established in 1992 and boasts an annual capacity of 10 million tons across various steel products, offers a significant advantage. They have the experience and infrastructure – integrating everything from ironmaking to rolling – to ensure consistent high-grade products like apo galvanized sheet.

|

Vendor Feature |

Baidy Steel (Example) |

Generic Competitor A (Estimate) |

Generic Competitor B (Estimate) |

|

Company History |

Established 1992 (Long-standing expertise) |

Newer (Less established) |

Mid-range (Moderate experience) |

|

Annual Production Capacity (Steel) |

10 Million Tons (Large scale) |

Around 1-3 Million Tons (Smaller) |

Approx. 5 Million Tons (Medium) |

|

Product Range |

Comprehensive (Structural, Automotive, Galvanized, etc.) |

Specialized (Limited range) |

Fairly broad (Some key omissions) |

|

Certifications/Standards |

ASTM, EN, DIN, GB, JIS (Full compliance) |

May vary (Regional only) |

Good (International, but fewer) |

|

Customization Options |

High (Spangles, packing, grades) |

Limited (Standard only) |

Moderate (Some flexibility) |

The Final Word

Ultimately, the demand for reliable, corrosion-resistant steel isn't going anywhere. From what I’ve observed, apo galvanized sheet, particularly products like the DX51D+Z, DX52D+Z, and S550GD+Z grades, represents the pinnacle of this technology. It’s engineered for resilience, backed by stringent standards, and serves as a foundational material for countless industries globally. When you're making critical choices for your projects, specifying high-quality galvanized steel isn't just a good idea; it's practically a necessity. It’s not just about meeting current needs but also ensuring a robust future for whatever you're building.

Authoritative Citations:

1. ASTM International. "ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process."

2. European Committee for Standardization. "EN 10346: Continuous hot-dip coated steel flat products – Technical delivery conditions."

3. Galvanizers Association. "The Performance of Hot Dip Galvanized Steel."

Steel Galvanized Automotive Manufacturer We are a foreign trade enterprise specializing in steel export, and Plate Corten Sheet Metal Manufacturer have been deeply engaged in the industry for 18 years, accumulating rich experience and abundant resources. Steel Galvanized Automotive Plate Corten We have a professional team composed of industry elites, who are not only proficient in all kinds of knowledge of steel and familiar with the rules of international trade, but also have keen market insight and excellent communication skills. Whether steel specifications, quality standards, or trade policies and market demand in different countries and regions,Sheet Metal Manufacturer our team can accurately grasp them and provide customers with all-round, one-stop professional services.Xingtai Baidy Steel Works