Bridge-grade strength that keeps projects on schedule

If you’re hunting for a high-strength bridge plate that welders don’t complain about and inspectors actually nod at, start with q420 steel. To be honest, the name sounds dry; on site, it’s the material folks reach for when span weights need trimming without sacrificing safety margins.

What’s happening in the market

Infrastructure owners are pushing for lighter superstructures, faster assembly, and measurable lifecycle gains. It seems that TMCP and controlled-rolled bridge plates (think q420 steel) are displacing older mild grades, especially where cold climates or fatigue details govern. Surprisingly, procurement teams now rank mill traceability and 3.2 certs almost as high as price.

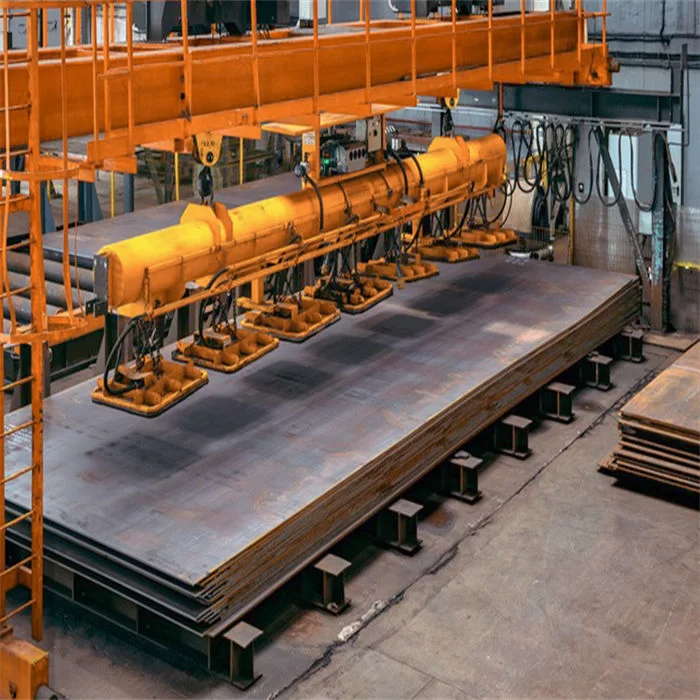

How it’s made (shop-floor view)

- Materials: HSLA design with microalloys (Nb–V–Ti), low P/S control for weldability.

- Methods: Typically TMCP or normalized rolling; some thinner sizes may be cold-rolled, depending on supply route.

- Heat treatment: Controlled cooling for fine bainite/ferrite; optional normalizing for thicker plates.

- Testing: Tensile per ISO 6892-1, Charpy V-notch per GB/T 229, UT per EN 10160 or GB/T 2970; MTC EN 10204 3.1/3.2.

- Service life: With proper coating systems, around 50–100 years; real-world use may vary with corrosion class.

Quick specs (field-friendly)

| Item | Spec (≈, typical) |

|---|---|

| Grade | q420 steel (Q420q D/E for -20°C/-40°C impact) |

| Yield / Tensile | ≥420 MPa yield; 520–680 MPa UTS, thickness dependent |

| Elongation | ≥17% (gauge and thickness dependent) |

| Charpy V-notch | ≥27–47 J at -20°C (D) / -40°C (E) |

| Sizes | 6–100 mm thick; 900–4800 mm wide; 3000–25000 mm long |

| Standards | GB/T, ISO, EN, ASTM/AASHTO equivalents where specified |

| Shapes | Plate; profiles (H/I-beam, channel, angle) on request |

Where it works best

Highway and railway bridges (girders, orthotropic decks), long-span arch ribs, cable-stayed pylons, seismic retrofit plate work, heavy temporary works. Fabricators tell me q420 steel hits a sweet spot: lighter than Q345 classes, but still friendly to weld (preheat, sure; drama, no).

Vendor snapshot (why procurement cares)

| Vendor | What stands out |

|---|---|

| Baidy Steel (Hebei, ROOM 1616, Shoujing E-World, Xindu District, Xingtai) | Bridge-grade focus; 6–100 mm range; 15–21 day delivery; EN 10204 3.1/3.2 MTC; UT to EN 10160; custom lengths |

| Integrated Mill A | TMCP plate with in-house blast/prime; stricter minimum order quantities |

| Trading House B | Fast spot allocations; mixed origin; check certs closely |

Customization, QA, and welding notes

- Custom cut-to-length, beveling, and profile rolling available; I-beams/H-beams on request.

- Inspection: VT, PT/MT as needed; UT level S1–S2; Z-direction (through-thickness) testing for high-restraint details.

- WPS/PQR: Preheat by carbon equivalent; common wires ER70/ER80; hydrogen control is non-negotiable.

- Certs: ISO 9001/14001, ISO 45001; CE marking for structural steel where required; traceable heats.

Mini case studies

– Provincial arch bridge: switching to q420 steel trimmed main rib weight ≈8%, enabling smaller cranes.

– Urban cable-stayed: D/E class plate met -40°C impact per spec; overnight weld repairs dropped noticeably, according to site QC.

Why teams pick it

Weight reduction without exotic metallurgy, reliable toughness in cold weather, and decent weldability. Many customers say the real win is schedule certainty: fewer re-tests, fewer surprises.

Standards you’ll see on drawings

GB/T 714 for bridge plates, ISO 6892-1 for tensile, GB/T 229 for Charpy, EN 10160 for UT, ASTM A709 and EN 10025-6 as common cross-references. Always match the project spec; equivalence isn’t automatic.

Authoritative citations

- GB/T 714 — Steel plates for bridges.

- ISO 6892-1 — Metallic materials — Tensile testing.

- GB/T 229 — Charpy pendulum impact test method for metals.

- EN 10160 — Ultrasonic testing of steel flat products.

- ASTM A709/A709M — Structural Steel for Bridges.

- EN 10025-6 — Hot rolled products of structural steels, high yield strength.

Steel Galvanized Automotive Manufacturer We are a foreign trade enterprise specializing in steel export, and Plate Corten Sheet Metal Manufacturer have been deeply engaged in the industry for 18 years, accumulating rich experience and abundant resources. Steel Galvanized Automotive Plate Corten We have a professional team composed of industry elites, who are not only proficient in all kinds of knowledge of steel and familiar with the rules of international trade, but also have keen market insight and excellent communication skills. Whether steel specifications, quality standards, or trade policies and market demand in different countries and regions,Sheet Metal Manufacturer our team can accurately grasp them and provide customers with all-round, one-stop professional services.Xingtai Baidy Steel Works